FORKLIFT SAFETY IN YOUR WORKPLACE

5 WAYS TO IMPROVE FORKLIFT SAFETY IN YOUR WORKPLACE

5 WAYS TO IMPROVE FORKLIFT SAFETY IN YOUR WORKPLACE

PROVIDE PROPER TRAINING FOR OPERATORS

Providing proper training for forklift operators is the first and most crucial step in improving forklift safety in the workplace. Operators must understand how to operate the forklift safely and know the necessary safety procedures. Employers should provide both classroom and hands-on training to operators, covering topics such as load capacities, speed limits, maneuvering, and emergency procedures.

Training should also include the proper use of personal protective equipment, such as hard hats (if needed), safety shoes, and high visibility vests. It's essential to ensure that all operators have the necessary knowledge and skills to operate a forklift safely before they start operating one in the workplace.

CONDUCT REGULAR MAINTENANCE AND INSPECTION

Regular maintenance and inspection of forklifts is essential to ensure they are in safe operating condition. Employers should conduct daily pre-operation checks to identify any defects or issues that could affect safety. These checks should include inspecting the brakes, steering, hydraulic system, and tires.

In addition to daily checks, employers should also schedule regular maintenance and inspections by qualified technicians. These technicians can perform more in-depth checks, including examining the electrical system and the engine, and identifying any potential safety hazards. Any defects or issues found during these checks should be addressed promptly.

ESTABLISH SAFE OPERATING PROCEDURES

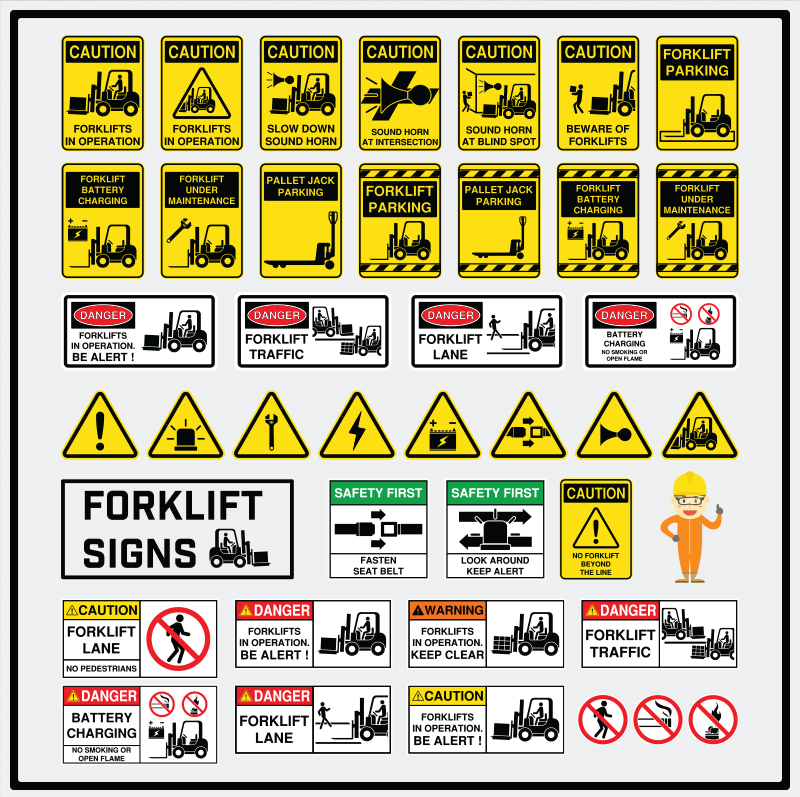

Safe operating procedures help minimize the risk of accidents and injuries when operating a forklift. These procedures should cover various aspects of forklift operation, including load handling, speed limits, turning and stopping, and traveling on ramps and inclines.

It's essential to ensure that all operators understand and follow these procedures to minimize the risk of accidents. Employers should also consider posting these procedures in visible locations in the workplace and ensure that all operators have access to them. Reviewing and updating these procedures periodically can help ensure they remain effective.

PROMOTE A CULTURE OF SAFETY

Employers should encourage a culture of safety in the workplace, promoting safe practices and behaviors among forklift operators and other employees. Operators should be encouraged to report any unsafe conditions, hazards, or behavior they observe. Employers should also provide incentives for safe practices and enforce consequences for unsafe behavior.

Employers can also consider conducting safety meetings and training sessions to promote safe work practices and discuss any issues or concerns. Encouraging open communication and a willingness to learn and improve can help create a culture of safety in the workplace.

USE TECHNOLOGY TO ENHANCE SAFETY

Technology can help improve forklift safety in the workplace by providing additional safety measures and alerts. For instance, proximity sensors and cameras can be installed on forklifts to help operators detect obstacles and navigate through narrow spaces. These sensors can also alert operators when they get too close to a person or object, helping to prevent accidents.

Smart forklifts can also be programmed to follow safe operating procedures, alerting operators when they're not being followed. These forklifts can also be equipped with GPS tracking systems, which can help employers monitor their use and identify potential safety hazards. Yale’s proprietary Yale Vision Telemetry and Yale Reliant OAS are the most advanced in the industry and can really help your operations by enhancing your technological advantage.

CONCLUSION

Forklift safety is critical in any workplace that uses forklifts. Employers can take several steps to improve safety, including providing proper training to operators, conducting regular maintenance and inspections, establishing safe operating procedures, promoting a culture of safety, and using technology to enhance safety. By implementing these steps, employers can create a safe and productive work environment for their employees.